Manufacturer & Exporter of Converting & Flexible Packaging Machinery

Call Us Now

+91 9512852352

Call Us Now

+91 9512852352

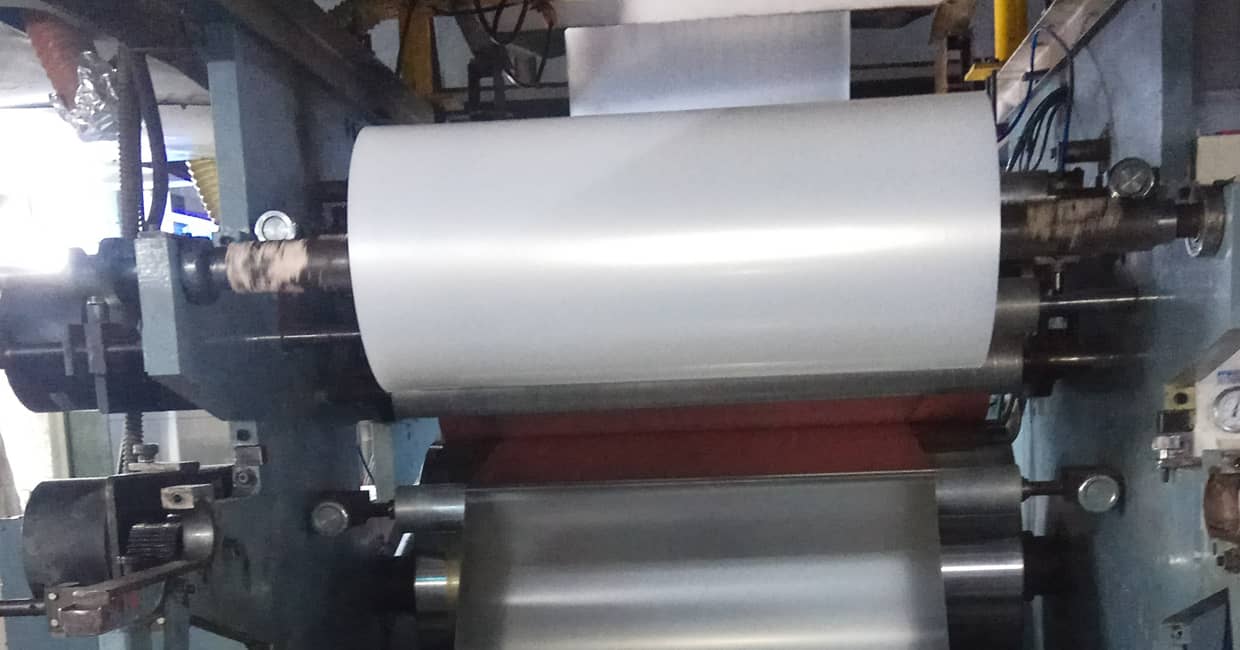

Heat & Press Lamination

Heat & Press Lamination

This modern new generation press is built to cater demands of the continuously evolving pharma packaging industries. Machine is designed ergonomically to cater medium and long run length job.

High productivity, low conversion cost, high quality lamination, fast job change-over are the key features.

| Standard Technical Specification | |

|---|---|

| Maximum web width | 1000 mm |

| Coating cylinder mesh | 180 mesh |

| Maximum mechanical speed | 125 m/min |

| Web tension range | 60 to 400 N |

| Standard drying hood length | 4.0 mtr |

| Reel diameter | 1000 mm |

Heat & Press Lamination Manufacture by AAYAR INTERNATIONAL

The Machine

The new generation Heat and Press Lamination Machine is led by PLC based HMI technology. By perfectly integration of advanced electronics and ergonomically designed mechanical components to deliver optimum performance, Better operational ease, faster print register response, higher productivity, lamination and primer coating quality, less waste, optimizing ink solvent and energy consumption, faster job changeover etc.

Simplex shafted unwind & rewind web tension controlled by using latest generation AC Motor and AC Drive The system maintains the set tension precisely throughout the reel run The system mainly composed of AC Drive and Motor, pneumatically loaded low friction dancing roller assembly and load cell for tension feed-back and actual tension display. The unwind & rewind arms move on high precision linear bushings and supported on ground chromeplated steel bars.

The laminator unit comprises a heated chrome plated, ground steel heating roll a high temprature rubber roll with chilling backup NIP roll. coated with Silicon rubber & chrome plated steel back-up roller which is driven by pneumatic pistons which can be adjusted at both ends. The rubber back-up roller is press against the steel roller for a total parallelism and to avoid any rubber roller flexion.

The laminator steel roll is driven by an independent motor synchronized with the coating unit motor by load cells, so the tension on the web carrying the adhesive to the point of lamination can be controlled with great prectsion.

CHILLING/ NIP CONSOLE: It is a Steel frame Structure with cross connection Tie Bar Plates, Chilling unit ensures that mechatronics are synchronized. Distinctively designed, and precisely machined, strong and robust steel frame structure, maintains accuracy over long durability and ensures reduced vibration even with optimum line speed. Two chilling rolls are tightly synchronized together with ac motor Driven by AC vector drive. The rotary union is provided to ensure chilled water circulation uniformly.

Coating unit is transmitted by an AC motor through a gear Box. Speed can be set by means of push buttons and monitored on the display (touch screen or HMI) The AC servo drive ensures that the set speed ts maintain.

Drying is obtaining by blowing hot air on the web through air nozzles. The optimized airflow minimizes heat consumption and avoids solvent retention in the laminated substrates

Electrical base 2 mtrs insulated drying chamber.

Single Drying hood pneumatically open able drying hood for web threading and cleaning.

Servo based or AC Motor shut circle regulator for web taking care of by utilizing most recent generatton of gadgets. A high-performance motion controller with its own intelligent software oversees and controls the entire machine.

The master operator control panel has a touch-screen interface that makes it easier to use. Wellbeing of administrator, machine and electronic modules are accomplished with the assistance of important equipment insurance and insightful programming schedules.

Master operator control console consists of IPC touch screen operator interface, located at rewind side and remote operator control panel at unwind side, as well as each and every printing units facilitates ease in operation.

Simplex shafted unwind & rewind web tension controlled by using latest generation AC Motor and AC Drive The system maintains the set tension precisely throughout the reel run The system mainly composed of AC Drive and Motor, pneumatically loaded low friction dancing roller assembly and load cell for tension feed-back and actual tension display. The unwind & rewind arms move on high precision linear bushings and supported on ground chromeplated steel bars.

Manufacturer & Exporter of Converting & Flexible Packaging Machinery is proudly powered by WordPress